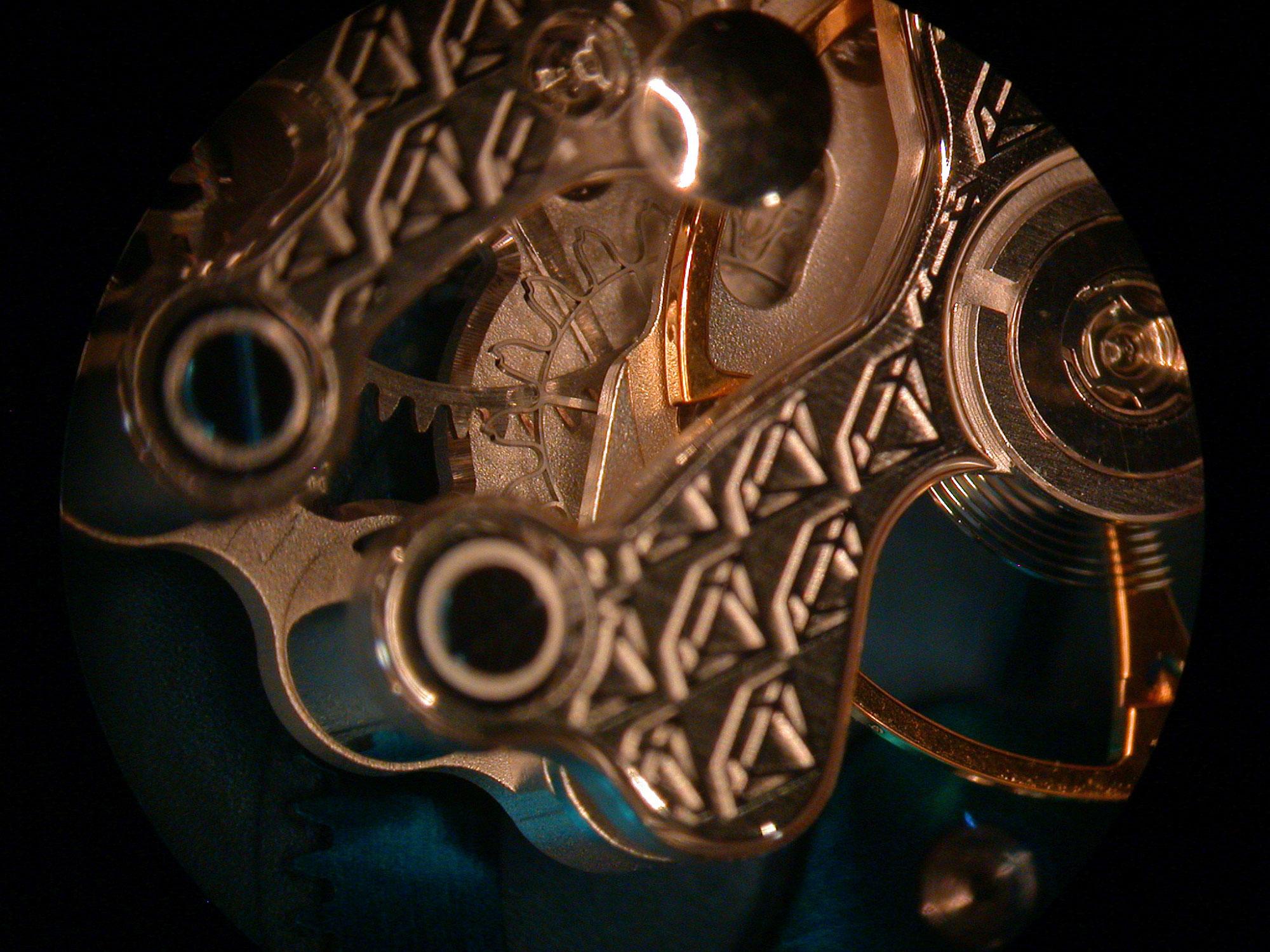

ALL DIAMOND (AD)

Full diamond components: 100 % diamond!

Diamond micro-components combine value and functionality. Especially in the watch industry the use of the world’s hardest material opens up completely new possibilities in terms of design and functionalities for a multitude of components. Due to the excellent combination of the materials properties of Diamond, extremely light weight and wear resistant components can be produced. Functional esthetics as well as wear resistance and outstanding frictional properties are among the characteristics of Diamond components.

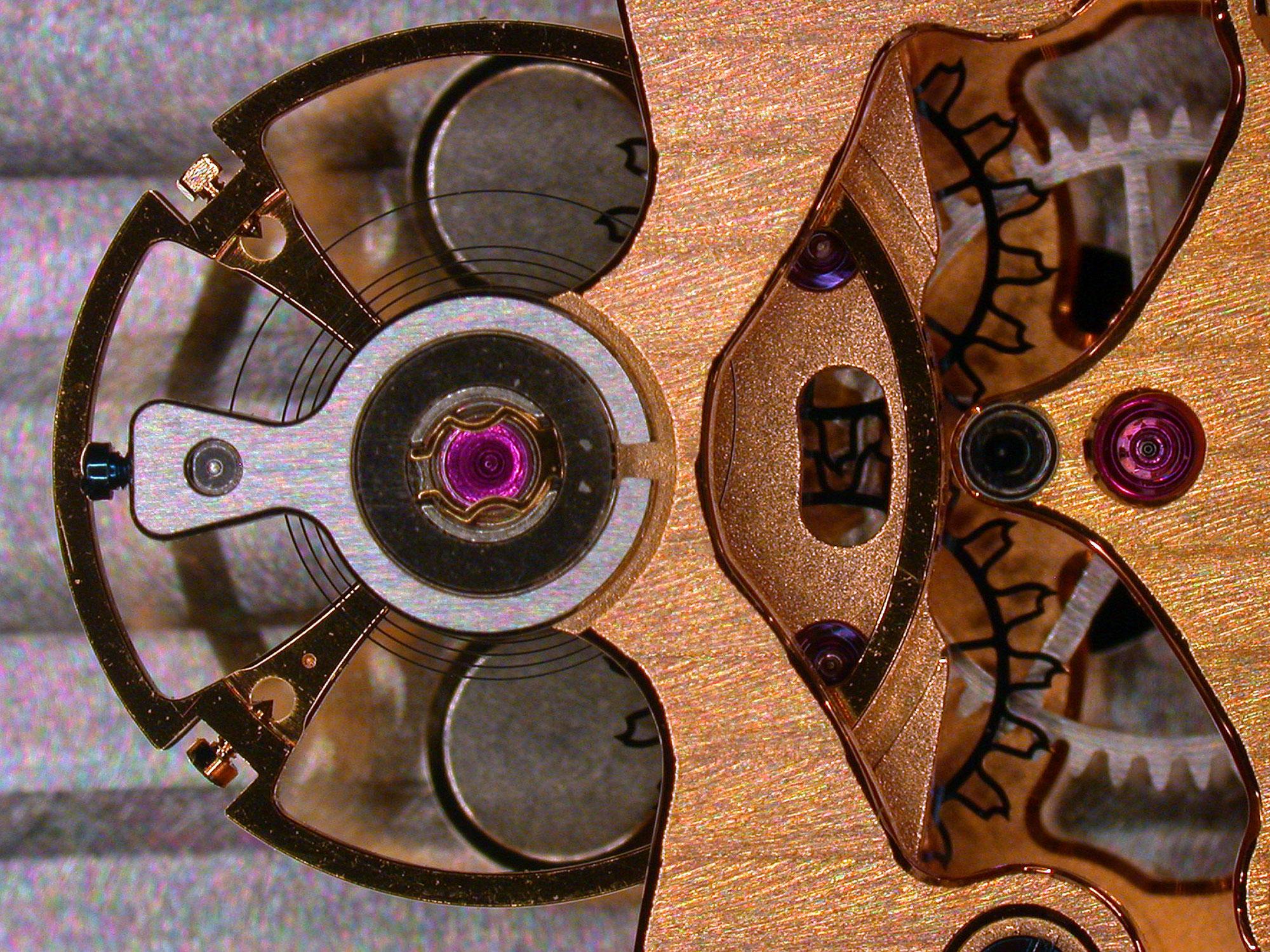

DIAMOND COATED SILICON (DCS)

Diamond coated Silicon components: An innovation!

By coating Silicon components with Diamond, the advantages of both materials can be favourably combined. Silicon is light weight and can be processed very precisely and reproducibly using micro-technical etching processes (DRIE) and therefore serves as a shaping substrate. The component gets its incomparable mechanical stability, functionality and durability from a thin 3D coating of Diamond. This produces mechanically robust and wear-less components that are cost-effective in series production.

The thin Diamond coating prevents efficiently damage from assembly or cleaning steps as well as chipping and fraction during operation.

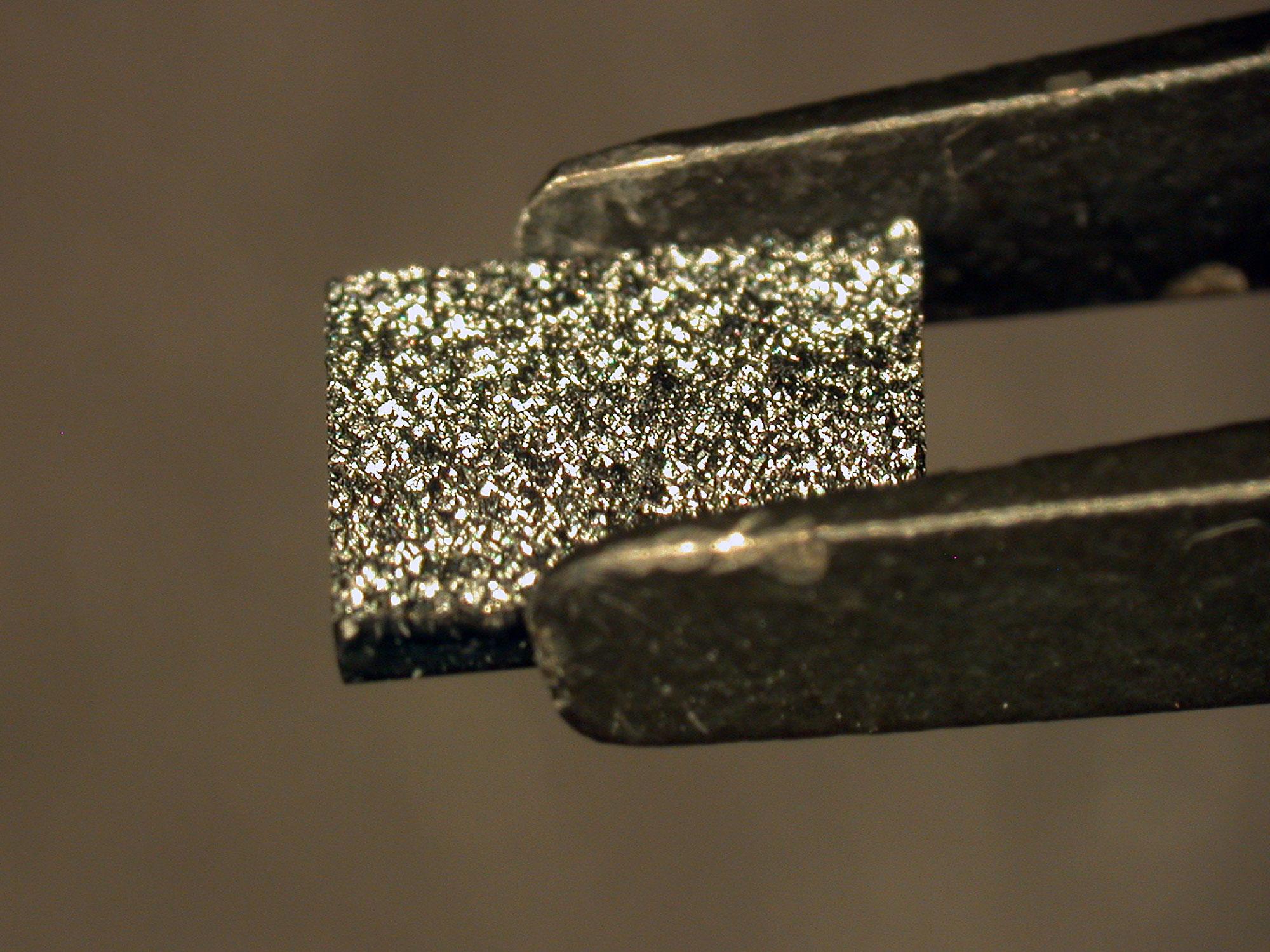

DECORATIVE DIAMOND (DD)

Decorative diamond coatings – A refinement of the highest quality

Decorative Diamond coatings are synthesized at temperatures between 700°C and 900°C utilizing gases such as methane and hydrogen. In this way millions of small Diamond crystals grow together in the form of a plate and create a brilliantly reflecting surface. Depending on the incidence of light and purity, the reflections and colour change. Decorative Diamond is also interesting for the jewellery industry, as it can be cut into any possible two-dimensional shape. Typical applications are watch dials, hands and similar applications.